Find Roofing Steel Panel Roll Forming Machine, Roof And Panel Roll Forming Machine, Roof And Wall Roll Forming Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 10 Days |

Model No.: FY-wall

Product Description

About the package and after-sale service of color steel roof and wall panel roll forming machine: It is nude, with waterproof cloth and stow-wood. The computer controlled cabinet is packed with waterproof cloth and box. The seller should guarantee equipment will be moisture-proof, anticorrosive, and will not be damaged during transportation. If buyer need, the seller will send one or two technician to the buyer`s factory to install & testing the machine, the buyer will assist the seller`s technician to get the visa and pay for the two-way flight tickets and local accommodation, visa cost.

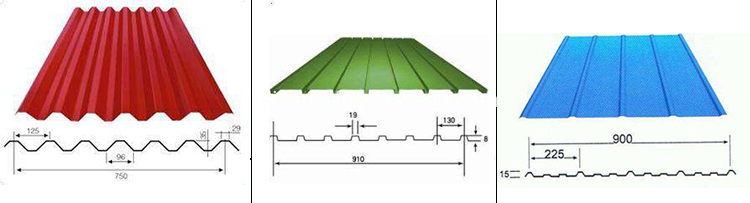

Finished Tile:

The roof and wall tile steel Roll Forming Machine production line is high precision and good productivity.

It needs 1-2 persons to handle the machine.

PLC control the machine, make the machine become more easily.

The cutting system can make the cut automatically with PLC control.

The whole work process is high safety level.

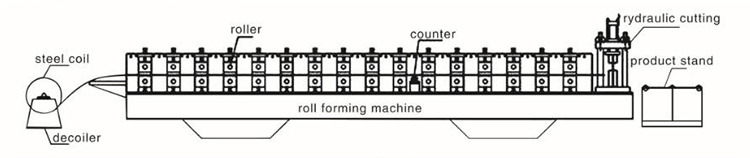

Roof and Wall Panel Roll Forming Machine Production Process:

manual uncoiler - roll forming machine - computer control system - hydraulic control system - cutting system - output table

Parameter of the Roof and Wall Panel Roll Forming Machine:

| Name | Wall and Roof Roll Forming Machine |

| Thickness | 0.3-0.8mm |

| Cutting type | Hydraulic type |

| Control system | PLC control |

| Width of the raw material | Width of the raw material |

| Shaft diameter | φ60mm |

| Computer screen | Touch screen |

| Rollers | 12 rows |

| Productivity | 8-10 m/min |

| Diameter of the roller | 70mm |

| Total power | 3kw |

| Dimension of major structure(L*W*H) | 6500mm*1300mm*1500mm |

Product Detail

Computer control cabinet:

The target piece's length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Loading capacity:5T

Inner diameter: 500-508mm

Roller system

Material of rollers:45# steel,roller surfaces polishing, hard plating .The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Cutting system

Material of the cutting:Cr12Mov with quenched treatment.It can decide cut panel dimension according to the hydraulic drive and PLC computer control system.

1.We have professional technicians for loading

Guaranteed the goods load into container without any damage.

2. Transportation : Machines need one 40 feet container to hold

3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Cangzhou Feiyang Machinery Manufacturing Co., Ltd. is a manufacturer of roll forming machine. We have been establishing and keeping good business relationship with more than 70 countries of worthy clients all over the world, mainly locating in East Europe, Middle East, South and West Asia, Africa and South America. We are proud of our own professional team with more than 18 years` experience in customized design and manufacture, installation and test, technical solution and after services. All the machines are with international quality standards and great after-sales services.

Main product catagories:

Sandwich Panel Roll Forming Machine,Roller Shutter Door Forming Machine,Double Layer Roll Forming Machine,Glazed Tile And Ridge Cap Roll Forming Machine,Corrugated Roof Roll Forming Machine,Roofing Sheet Roll Forming Machine

and various kinds full-automatic cold bending roll forming equipment.We do firmly believe :technological innovation ,making every detail of the product perfect is our ambition ever.

Product Categories : Wall Panel Roll Forming Machine